Discover High Quality: Aftermarket Construction Parts Comparison

Wiki Article

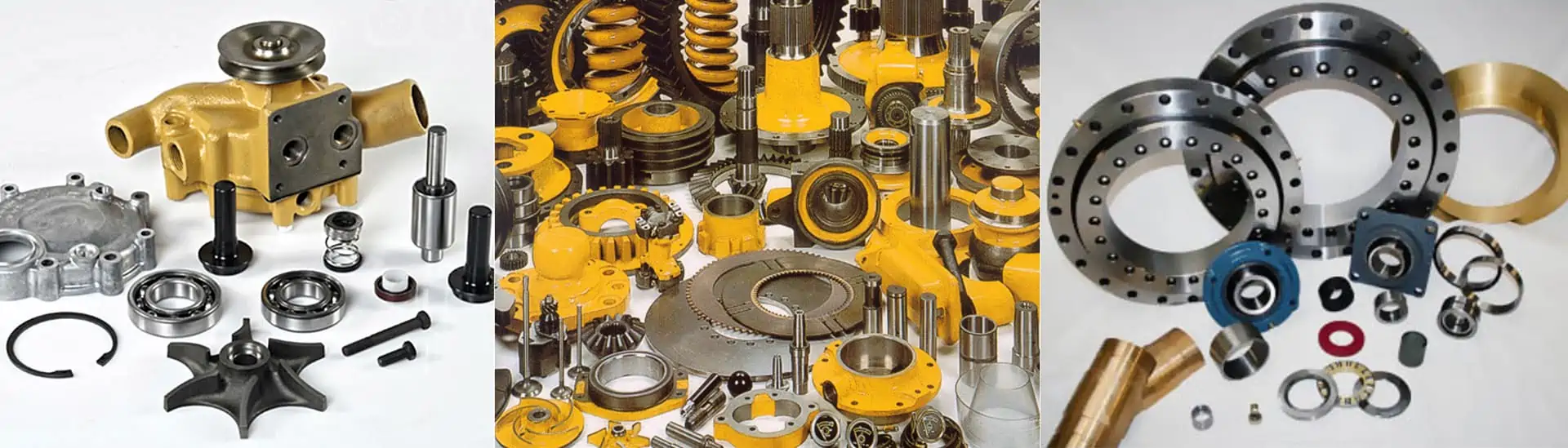

Enhance Your Heavy Machinery With Quality Aftermarket Building And Construction Parts

Enhancing heavy equipment with high quality aftermarket building and construction parts can significantly influence the performance and longevity of your equipment. Whether you are looking to enhance effectiveness, toughness, or total capability, the decision to purchase aftermarket parts holds the possibility for significant benefits. From raised productivity to cost-effective services, aftermarket building components offer a variety of benefits that deal with the varied requirements of hefty machinery drivers. By discovering the intricacies of aftermarket parts, one can unlock a realm of possibilities for elevating the efficiency of their equipment.Advantages of Aftermarket Building And Construction Parts

Enhancing heavy machinery with aftermarket building and construction components can substantially boost performance and long life. Aftermarket components are commonly created with updated technologies and products, which can result in equipment that can endure more extensive operating conditions.In addition, aftermarket building and construction parts can use expense financial savings contrasted to purchasing original tools manufacturer (OEM) components. While OEM components are generally more expensive because of brand name acknowledgment and exclusivity, aftermarket alternatives offer an even more budget-friendly choice without compromising on high quality. This cost-effectiveness can be particularly useful for business wanting to maximize their operational expenditures without sacrificing the efficiency of their heavy equipment.

Variables to Think About When Choosing Components

When picking building and construction parts for hefty equipment, it is crucial to very carefully take into consideration various variables to guarantee ideal performance and compatibility. One essential factor to take into consideration is the high quality of the components. Choosing for top notch aftermarket construction components can significantly affect the total efficiency and longevity of the equipment. It is vital to choose parts from reputable suppliers known for their trusted and sturdy items.

An additional element to take into consideration is compatibility. Making certain that the building components are suitable with the particular make and design of the machinery is essential to avoid any kind of operational concerns or damage. This consists of confirming the dimensions, requirements, and any type of added demands for smooth assimilation.

Furthermore, thinking about the cost-effectiveness of the components is crucial. While quality needs to not be jeopardized, selecting aftermarket parts that offer a great balance in between high quality and cost can aid in maximizing the value of the financial investment.

Finally, availability and consumer support should additionally be thought about. Go with building and construction parts that are conveniently available and backed by exceptional customer assistance to deal with any kind of queries or concerns without delay. By thoroughly evaluating these aspects, you can make educated decisions when selecting aftermarket construction components for your hefty machinery.

Installment Tips for Aftermarket Components

To make certain a smooth and effective setup process for aftermarket construction components on hefty equipment, careful interest to detail and adherence to manufacturer guidelines are paramount. Before starting the setup, it is vital to completely examine the aftermarket parts to validate that they match the specs of the original parts and are without any kind of issues. Furthermore, organizing the job location and guaranteeing that the necessary devices are easily available can aid improve the installation procedure.Adhering to the producer's installation guidelines is vital to guarantee correct fit and performance of the aftermarket parts. Any type of deviation from these standards might lead to substandard efficiency or even possible safety threats. It is likewise advisable to record the installation process, consisting of any kind of modifications made or obstacles experienced, for future referral.

Lastly, performing a final assessment after the installation is total can aid determine any kind of issues or mistakes that might have been neglected - aftermarket construction parts. Examining the machinery to make sure that the aftermarket components are functioning properly is description a crucial final action in the installation process

Maintenance Standards for Upgraded Machinery

Routinely arranged maintenance checks are vital to make sure that all aftermarket components are working properly. This includes examining components for wear and tear, lubricating moving components, and changing filters as required.In enhancement to routine maintenance, operators should additionally focus on any kind of uncommon noises, vibrations, or performance issues that may emerge. Attending to these problems quickly can prevent further damages to the machinery and its aftermarket parts. Maintaining in-depth records of maintenance activities, repairs, and component replacements can help track the total health and wellness of the upgraded equipment and recognize any type of recurring concerns.

Furthermore, appropriate storage and cleansing procedures need to be complied with to protect the equipment from environmental factors that can accelerate use on aftermarket parts (aftermarket construction parts). By adhering to these upkeep guidelines carefully, operators can make the most of the advantages of their upgraded equipment and ensure its ongoing reliability at work site

Cost-efficient Upgrades for Heavy Equipment

Implementing calculated upgrades can dramatically enhance the performance and effectiveness of hefty equipment while keeping cost-effectiveness. When considering affordable upgrades for heavy equipment, it is important to prioritize improvements that use the most substantial effect on productivity without breaking the budget plan.An additional cost-efficient upgrade is the assimilation of GPS technology, which can optimize route planning, increase fuel efficiency, and improve overall task site efficiency. Upgrading to more resilient tires or tracks can also be a wise investment, as they can enhance traction, reduce wear and tear, and inevitably expand the life-span of the equipment. Additionally, retrofitting older machinery with energy-efficient components, such as LED lights or boosted hydraulic systems, can bring about lasting expense savings through reduced energy intake and upkeep costs. By thoroughly selecting and implementing these cost-effective upgrades, hefty equipment operators can make the most of performance and performance while staying within budget restraints.

Verdict

To conclude, aftermarket construction components provide numerous advantages for enhancing heavy equipment. By very carefully considering aspects such as compatibility and quality, choosing the right parts can boost efficiency and expand the life expectancy of equipment. Proper installation and routine upkeep are crucial for making sure optimal performance. On the whole, cost-efficient upgrades with aftermarket components can cause enhanced performance and efficiency in building and construction straight from the source procedures.Enhancing Learn More Here hefty equipment with quality aftermarket building components can dramatically influence the performance and longevity of your equipment.Enhancing heavy machinery with aftermarket building parts can significantly enhance efficiency and durability.Moreover, aftermarket building and construction components can supply price financial savings contrasted to acquiring initial tools supplier (OEM) parts.To guarantee a efficient and seamless installation process for aftermarket construction components on hefty equipment, careful interest to detail and adherence to producer standards are extremely important. Prior to starting the setup, it is important to completely examine the aftermarket parts to validate that they match the requirements of the initial parts and are totally free from any defects.

Report this wiki page